There are two options for cushioning the car body - dependent and independent suspension. In modern passenger cars, as a rule, independent suspension is used. This implies that the wheels on one axle do not have a rigid connection with each other, and a change in position relative to the car body of one in any way or almost does not affect the position of the second. At the same time, the angles of camber and toe-in of the wheels can vary within fairly significant limits.

Oscillating axle suspension

This is one of the simplest and cheapest suspension types. Its main element is the axle shafts, which have hinges at the inner ends, through which they are connected to the differential. The outer ends are rigidly connected to the hub. Springs or leaf springs act as elastic elements. The design feature is that when hitting any obstacle, the position of the wheel relative to the axle shaft remains invariably perpendicular.

Additionally, the design may include longitudinal or transverse levers designed to damp the reaction forces of the road. Such a device had the rear suspension of many rear-wheel drive cars produced in the middle of the last century. In the USSR, the suspension of the ZAZ-965 car can be cited as an example.

The disadvantage of such an independent suspension is its kinematic imperfection. This means that when driving on uneven roads, camber and track width change over a wide range, which negatively affects handling. This becomes especially noticeable at speeds over 60 km / h. Among the advantages are a simple device, cheap maintenance and repair.

Trailing arm suspension

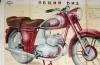

There are two types of trailing arm independent suspension. In the first, springs are used as elastic elements, and in the second, torsion bars. The vehicle's wheels are attached to trailing arms, which in turn are movably articulated with the frame or body. Such a suspension found its application in many French front-wheel drive cars, produced in the 70-80s, as well as in motor scooters and motorcycles.

Among the advantages of this design are also a simple device, cheap manufacturing, maintenance and repair, as well as the ability to make the floor of the car completely flat. It has much more disadvantages: while driving, the wheelbase changes within significant limits, and in corners the car rolls heavily, which means that the handling is far from ideal.

Slant-arm suspension

The device of such a suspension is in many respects similar to the previous one, the only difference is that the swing axes of the levers are located at an oblique angle. Thanks to this, the change in the wheelbase of the car is minimized, and body rolls have almost no effect on the angle of inclination of the wheels of the car, however, on irregularities, the track width changes, and the toe and camber angles change, which means that controllability deteriorates. Coiled springs, torsion bars or pneumatic springs were used in the role of elastic elements. This version of independent suspension was more often used for the rear axle of cars, the only exception was the Czech Trabant, the front suspension of which was made according to this scheme.

There are two types of oblique arm suspensions:

- single-hinged;

- double-hinged.

In the first case, the axle shaft has one hinge, and the swing axis of the lever passes through the hinge and is located at an angle of 45 degrees to the longitudinal axis of the machine. This design is cheaper, but also not kinematically perfect, therefore it was used only on light and slow cars (ZAZ-965, Fiat-133).

In the second case, the axle shafts have two hinges, external and internal, and the swing axis of the lever itself does not pass through the internal hinge. It is located at an angle of 10-25 degrees to the longitudinal axis of the car, this is preferable for the suspension kinematics since the deviations of the track, wheelbase and camber values \u200b\u200bremain within normal limits. The rear suspension of ZAZ-968, Ford Sierra, Opel Senator and many others had such a device.

Trailing and wishbone suspension

A very complex, and therefore rare design. It can be considered a kind of MacPherson suspension, but in order to relieve the mudguard of the wing, the springs were placed horizontally along the car. The rear end of the spring rests against the partition between the engine compartment and the passenger compartment. In order to transfer the force from the shock absorber to the spring, it was necessary to introduce an additional lever swinging in a vertical longitudinal plane along each side. One end of the lever is pivotally connected to the top of the shock absorber, and the other is also pivotally connected to the partition. In the middle, the lever has a spring stop.

The front suspension of some Rover models is made according to this scheme. It has no particular advantages over McPherson, and has retained all the kinematic disadvantages, but has lost its main advantages, such as compactness, technological simplicity, and a small number of hinged joints.

Double trailing arm suspension

Its second name is "Porsche system", after the name of the inventor. In such a suspension, there are two trailing arms on each side of the car, and torsion shafts located one above the other play the role of elastic elements. Such a device had the front suspension of cars, the engine of which is located at the back (models of early sports cars Porsche, Volkswagen Beetle and Volkswagen Transporter of the first generation).

The independent trailing arm suspension is compact, in addition, it allows the interior to be moved forward, and the legs of the front passenger and the driver are placed between the wheel arches, which means that the length of the car is reduced. Of the minuses, we can note changes in the wheelbase when hitting obstacles and a change in wheel camber when the body rolls. Also, due to the fact that the levers are subjected to constant strong forces of bending and torsion, they have to be strengthened, increasing size and weight.

Double wishbone suspension

The device of this type of independent suspension is as follows: on both sides of the car, two levers are located transversely, which on one side are movably connected to the body, cross member or frame, and on the other - to the shock absorber strut. If it is a front suspension, then the strut is swivel, with ball joints having two degrees of freedom, if the rear one, then the strut is non-swiveling, with cylindrical joints having one degree of freedom.

Various elastic elements are used:

- coil springs;

- torsion bars;

- springs;

- hydropneumatic elements;

- pneumatic cylinders.

On many vehicles, suspension elements are attached to a cross member that is rigidly connected to the body. This means that you can remove the entire structure as a whole, as a separate unit, and carry out repairs in more convenient conditions. In addition, the manufacturer has the opportunity to choose the most optimal way of placing the levers, thereby rigidly setting the required parameters. This ensures good handling. For this reason, double wishbone suspension is used in racing cars. From a kinematic point of view, this suspension has no drawbacks.

Multi-link suspension

The most complex device has a multi-link suspension. It is similar in structure to the double wishbone suspension and is used mainly on the rear axle of class D and higher cars, although it is sometimes found on class C cars. Each of the levers is responsible for a certain parameter of the wheel's behavior on the road.

The multi-link suspension provides the car with the best handling. Thanks to it, you can achieve the effect of steering the rear wheels, which allows you to reduce the turning radius of the car, and better allows you to keep the trajectory in turns.

The multi-link suspension also has drawbacks, however, they are not of an operational nature - the cost of the structure is high, the complexity of design and repair.

MacPherson type suspension

The front suspension of most modern cars of the A - C class is made according to the MacPherson type. The main structural elements are shock absorbers and a coil spring as an elastic element. In more detail, the MacPherson suspension device, its advantages and disadvantages are discussed in a separate article.

Instead of an afterword

In modern automotive industry, dependent and independent suspension is used. One should not assume that one of them is better than the other, since their purpose and scope are different. Under a solid axle, the ground clearance always remains unchanged, and this is a valuable quality for a car that drives mainly off-road. That is why SUVs use a spring or leaf spring rear suspension with a continuous axle. An independent car suspension cannot provide this, and the real ground clearance may be less than the declared one, but its element is asphalt roads, on which it undoubtedly wins over the bridge in handling and comfort.

In the material, we talked about the existing types of suspensions, and dwelt in detail on the types of dependent suspension. Today we will talk about the types of independent suspension.

So, there are nine types of independent suspensions, moreover, two of them have several varieties.

The first type of suspension of this type is with oscillating axle shafts. Already from the name itself it is clear that the main structural elements of such a suspension are the axle shafts. There are hinges at their inner ends, with which the axle shafts are attached to the main gear with a differential. The outer ends of the axle shafts are firmly connected to the wheels. Springs or springs serve as elastic elements in such suspensions. The peculiarity of this independent suspension design is that when hitting an obstacle, the wheel always retains its perpendicular position relative to the axle shaft, and the reaction forces of the road are dampened by the axle shafts themselves and their hinges.

In some subspecies of such an independent suspension, transverse or trailing arms are used, which act as "dampers" of road reaction forces. As a rule, the design of such a suspension was used on the rear axle for rear-wheel drive vehicles. Such suspensions were installed on Ford, Mercedes-Benz and Chevrolet cars of the mid-20th century. In the USSR, a similar suspension was installed on ZAZ cars. The advantages of a suspension with oscillating axle shafts include simplicity of design, low cost of maintenance and repair. The disadvantages are large fluctuations in track and camber when hitting obstacles. These disadvantages were especially evident when driving at speeds over 60 km / h, which negatively affected the car's handling.

The second type of independent suspension is on trailing arms. This suspension has two subspecies: spring (elastic elements - springs) and torsion (elastic elements - torsion bars). The peculiarity of the suspension design is the arrangement of the wheels on the trailing arms, which are movably attached to the body or frame of the car. This type of suspension was installed on the rear axles of Citroen, Austin cars, scooters and small trailers.

The advantages of this type of suspension are the simplicity of its design, which, in turn (especially in the torsion subspecies), made it possible to make the floor of the car flat, and the low cost of manufacturing, repair and maintenance. It has more disadvantages: significant changes in the parameters of the wheelbase when driving, large rolls in corners (due to a low roll center).

The third type of independent suspension is on oblique levers. By its design, it resembles a suspension on trailing arms, with the difference that the swinging axes of the arms are at an oblique angle. It, in turn, is divided into two subspecies: with single-hinged semi-axles with diagonal levers (located at an angle of 45 degrees) and double-hinged semi-shafts with oblique levers (hinges are located at both ends of the semi-shafts). This type of suspension was mainly installed on the rear axle (on cars of such brands as Ford, Mercedes-Benz, Opel, Porsche, Fiat and ZAZ), with a suspension on oblique arms on the front axle, Trabant was manufactured. The advantages of such a suspension, in comparison with the suspension on the trailing arms, were the reduction of fluctuations in the parameters of the wheelbase, the roll of the car in a turn. The disadvantages of this type of suspension include a strong change in toe and camber, a high roll center (for a subspecies with single-joint semi-axles).

The fourth type of independent suspension is on trailing and transverse levers. The design of this suspension uses a guide strut, which uses a trailing arm to take over the upper support forces to relieve the mudguard of the fender. This type of suspension is cumbersome, structurally complex, and therefore unpopular. Rover, Glas cars had such a suspension. As such, the advantages of the suspension on the longitudinal and transverse levers are few: this is a large distance in height between the support nodes (reduces the effect of forces on the fastening of the suspension to the body) and the variability of the structural travel of the suspension. The disadvantages include the complexity of the design (a large number of parts - hinges, levers), large dimensions, poor kinematic parameters (a significant change in the camber angle with large suspension strokes).

The fifth type of independent suspension is on double trailing arms. The peculiarity of its design is that on each side of the axle there are two longitudinal levers, which are united by transverse torsion bars, which play the role of elastic suspension elements. As a rule, such a suspension was installed on the front axle of rear-engined Volkswagen and Porsche cars of the early - mid-20th century. The advantages of such a suspension: compactness, the ability to move the front of the car body forward (which had a positive effect on the comfort of the driver and front passenger). Cons: changing the parameters of the wheelbase when hitting obstacles, a large mass of levers (increases the weight of the car).

The sixth type of suspension is double wishbone. It, depending on the elastic elements used, is divided into five subspecies: spring, torsion, spring, hydropneumatic and pneumatic. The commonality of this design for all subspecies is the presence of transverse levers, which, with their inner ends, are movably articulated with the body or frame of the machine, and with their inner ends, with swivel (for the front suspension, with ball joints with two degrees of freedom) and non-swivel (for the rear suspension, with cylindrical hinges with one degree of freedom) rack. The upper arm in such a suspension is shorter than the lower one; they can be located both parallel to each other and at a certain angle.

The spring suspension on double wishbones has coil springs in its design, which play the role of an elastic element.

They are located between the wishbones, or above the upper control arm with an emphasis on the mudguard of the wing. Jaguar cars have such a suspension structure.

The double wishbone torsion bar suspension has longitudinal torsion bars attached to the lower links as an elastic element. In this type of suspension, they can be attached both longitudinally and transversely. With this suspension, cars of the brands Packard, Chrysler, Fiat, Simka and ZIL were produced.

The sprung suspension uses springs as an elastic element, which are located transversely to double levers.

Suspensions with one, two, four springs were installed on cars, which were attached at one or two points. Also in the first half of the twentieth century, cars were produced that had four trailing springs (two on each side of the side), located transversely. The sprung suspension structure was used by Tatra, Fiat, Ford, Autobianci, Chevrolet, Lancia, Packard.

In the hydropneumatic and pneumatic subspecies of independent suspension on double wishbones, the role of elastic elements is played by pneumatic cylinders or hydropneumatic elements, combined into one whole with the power steering system and the hydraulic brake system. Air suspension on double wishbones was used by Mercedes-Benz, Austin, and hydropneumatic suspensions were common in Citroen models.

The advantages of the double wishbone independent suspension are structural and functional. The design of such a suspension is unique in that all its elements can be attached to a special cross member, which is rigidly mounted in the body or frame. Thus, during repairs, this suspension can be removed completely as a separate unit for repair or replacement. The functional advantage is that by choosing a certain geometry of the placement of the arms, you can rigidly set any desired suspension settings. This contributes to a high degree of vehicle handling, which is why double wishbone suspensions are often used in sports cars.

The seventh type of independent suspension is “candle”. It became the structural forerunner of the MacPherson suspension. In the design of this type of suspension, a rigid frame is used, on which a steering knuckle is mounted. From above it is supported by a spring or spring. When hitting an obstacle, the steering knuckle slides up and down the frame to provide cushioning. Today, only sports cars from the Morgan company have this suspension; this type was most widespread at the beginning of the twentieth century. The advantages of this suspension include the simplicity and compactness of the design, low weight, and high reliability. The disadvantages are large longitudinal vibrations.

The eighth type of independent suspension -. In its design, shock-absorbing struts are used, and a coil spring acts as an elastic element.

Fits primarily on the front axle. We will consider in more detail the design, pros and cons of this suspension in a separate material. The McPherson suspension is installed on most modern passenger cars.

The ninth type of independent (semi-independent) suspension is a torsion-link suspension, which combines two trailing arms and a torsion-bar twisted beam in its design. This type of suspension has been used on the rear axle of front wheel drive vehicles. The torsion bar suspension was developed by Audi, on whose models it was installed in the 1970s and 90s.

Today, Chinese companies rarely use such a suspension on budget models. The advantages of such a suspension include their durability and reliability, and the relative simplicity of the design. By cons - rigidity, which affects the comfort of passengers in the rear row of the car, a predisposition to roll in a turn (due to the low location of the roll center).

Let's go straight to the topic without shelving . Moreover, the topics are quite interesting, although this is the second in a row about cars. I'm afraid of the female readers and pedestrians, this is not entirely to their liking, but that's how it happened Listening to the topic from :

“How does car suspension work? Suspension types? What determines the rigidity of the machine? What is "hard, soft, elastic ..." suspension "

We tell ... about some options (and oh, how many of them actually turn out to be!)

The suspension carries out an elastic connection of the body or frame of the car with the axles or directly with the wheels, softening shocks and shocks that occur when the wheels hit the bumps in the road. In this article, we will try to consider the most popular types of car suspensions.

1. Independent suspension on two wishbones.

Two forked levers, usually triangular in shape, guide the rolling of the wheel. The rolling axis of the arms is parallel to the longitudinal axis of the vehicle. Over the years, double wishbone independent suspension has become standard equipment in cars. At one time, she proved the following indisputable advantages:

Light unsprung weight

Little space requirement

Possibility of adjusting vehicle handling

Available combination with front-wheel drive

The main advantage of such a suspension is the ability for the designer, by choosing a certain geometry of the levers, to rigidly set all the main settings of the suspension - changing the camber and track during compression and rebound strokes, the height of the longitudinal and transverse roll centers, and so on. In addition, such a suspension is often completely mounted on a cross member attached to the body or frame, and thus is a separate unit that can be completely removed from the vehicle for repair or replacement.

From the point of view of kinematics and controllability, double wishbones are considered the most optimal and perfect type, which leads to a very widespread use of such a suspension in sports and racing cars. In particular, all modern Formula 1 race cars have just such a suspension both at the front and at the rear. Most sports cars and executive sedans these days also use this type of suspension on both axles.

Advantages: one of the most optimal suspension schemes and that says it all.

Disadvantages: layout restrictions associated with the length of the wishbones (the suspension itself "eats away" a fairly large space in the engine or luggage compartment).

2. Independent slant-arm suspension.

The pivot axle is located diagonally to the longitudinal axis of the vehicle and tilted slightly towards the middle of the vehicle. This type of suspension cannot be fitted to front-wheel drive vehicles, although it has proven to be effective in rear-wheel drive small and medium-sized vehicles.

TOtrailing-arm or slant-arm mounting is almost never used in modern cars, but the presence of this type of suspension, for example, in the classic Porsche 911, is definitely a topic for discussion.

Advantages:

Disadvantages:

3. Oscillating axle independent suspension.

The independent swing-axle suspension is based on Rumpler's patent from 1903, which was used by Daimler-Benz until the seventies of the 20th century. The left axle tube is rigidly connected to the final drive housing, and the right tube has a spring connection.

4. Independent trailing arm suspension.

The independent trailing arm suspension was patented by Porsche. TOtrailing-arm or slant-arm mounting is almost never used in modern cars, but the presence of this type of suspension, for example, in the classic Porsche 911, is definitely a topic for discussion. In contrast to other solutions, the advantage of this type of suspension was that this type of axle was connected to a transverse torsion spring bar, which created more space. The problem, however, was that there were reactions of strong lateral vibrations of the car, which could lead to a loss of control, which, for example, "became famous" of the "Citroen" model "2 CV".

This type of independent suspension is simple but imperfect. When such a suspension is operating, the wheelbase of the car changes within a fairly wide range, although the track remains constant. When turning, the wheels tilt in it together with the body significantly more than in other suspension designs. Oblique levers allow to partially get rid of the main drawbacks of the suspension on the trailing arms, but when the effect of body roll on the inclination of the wheels decreases, a change in track appears, which also affects handling and stability.

Advantages: simplicity, low cost, relative compactness.

Disadvantages: outdated design, extremely far from perfect.

5. Independent suspension with wishbone and spring strut (McPherson).

The so-called "McPherson suspension" was patented in 1945. It was a further development of the double wishbone suspension, in which the upper control arm was replaced by a vertical guide. The McPherson struts are designed to be used with both front and rear axles. In this case, the wheel hub is connected to the telescopic tube. The entire rack is connected to the front (steerable) wheels by means of hinges.

MacPherson first used the 1948 Ford Vedet model produced by the French subsidiary on a production car. It was later used on the Ford Zephyr and Ford Consul, which also claim to be the first high-volume vehicles with such a suspension, as the Vedette plant in Poissy initially had great difficulty getting the new model into production.

In many ways, similar suspensions were developed earlier, right up to the very beginning of the 20th century, in particular, a very similar type was developed by Fiat engineer Guido Fornaca in the mid-twenties - it is believed that MacPherson partially took advantage of his developments.

The immediate ancestor of this type of suspension is a type of front suspension with two wishbones of unequal length, in which the spring in a single block with a shock absorber was moved into the space above the upper arm. This made the suspension more compact, and made it possible to pass a semi-axle with a hinge between the levers on a front-wheel drive car.

Replacing the upper arm with a ball joint and a shock absorber and spring block located above it with a shock absorber strut with a swivel joint attached to the wing mudguard, MacPherson received a compact, structurally simple and cheap suspension named after him, which was soon used on many Ford models European market.

In the original version of such a suspension, the ball joint was located on the continuation of the axis of the shock absorber, so the axis of the shock absorber was also the axis of rotation of the wheel. Later, for example, on the Audi 80 and Volkswagen Passat of the first generations, the ball joint began to be displaced outward to the wheel, which made it possible to obtain smaller and even negative values \u200b\u200bof the run-in shoulder.

This suspension became widespread only in the seventies, when technological problems were finally solved, in particular, the mass production of shock absorber struts with the required resource. Due to its manufacturability and low cost, this type of suspension subsequently quickly found very widespread use in the automotive industry, despite a number of disadvantages.

In the eighties, there was a trend towards widespread use of MacPherson strut suspension, including on large and relatively expensive cars. However, subsequently, the need for a further increase in technical and consumer qualities led to the return on many relatively expensive cars to a double wishbone suspension, which is more expensive to manufacture, but has better kinematic parameters and increases driving comfort.

Chapman rear suspension - MacPherson strut version for the rear axle.

MacPherson designed his suspension to be installed on all wheels of the car, both front and rear - in particular, this is how it was used in the Chevrolet Cadet project. However, on the first production models, the suspension of his development was used only in front, and the rear, for reasons of simplification and reduction in cost, remained traditional, dependent with a rigid drive axle on longitudinal springs.

Only in 1957, Lotus engineer Colin Chapman used a similar suspension for the rear wheels of the Lotus Elite model, so it is commonly called "Chapman's suspension" in English-speaking countries. But, for example, in Germany such a difference is not made, and the combination "MacPherson strut rear suspension" is considered quite acceptable.

The most significant advantages of the system are its compactness and low unsprung weight. Suspension "McPherson" has become widespread due to its low cost, ease of manufacture, compactness, as well as the possibility of further refinement.

6. Independent suspension with two transverse springs.

In 1963, General Motors developed the Corvette with an exceptional suspension solution - an independent suspension with two transverse springs. In the past, coil springs were preferred over springs. Later, in 1985, the first production of the Corvette was again equipped with a suspension with transverse springs made of plastic. However, in general, these designs were not successful.

7. Independent candle suspension.

This type of suspension was installed on early Madeleys, for example, on the Lancia Lambda (1928). In this type of suspension, the wheel, together with the steering knuckle, moves along a vertical guide mounted inside the wheel casing. A coil spring is installed inside or outside this guide. This design, however, does not provide the wheel alignment required for optimal road contact and handling.

FROMthe most common type of independent suspension in a passenger car today. It is characterized by simplicity, low cost, compactness and relatively good kinematics.

It is a suspension on a rail and one wishbone, sometimes with an additional trailing link. The main idea when designing this suspension scheme was by no means handling and comfort, but compactness and simplicity. With fairly average indicators, multiplied by the need to seriously strengthen the place of attachment of the rack to the body and a rather serious problem of road noise transmitted to the body (and a whole bunch of shortcomings), the suspension turned out to be so technologically advanced and so liked the linkers that it is still used almost everywhere ... In fact, only this suspension allows designers to position the power unit transversely. MacPherson strut suspension can be used for both the front and rear wheels. However, in English-speaking countries, a similar rear-wheel suspension is commonly referred to as "Chapman's suspension". Also, this suspension is sometimes called the term "candle suspension" or "swinging candle". Today, there is a tendency to move from the classic MacPherson strut to a scheme with an additional upper wishbone (a kind of hybrid of MacPherson strut and wishbone suspension is obtained), which allows, while maintaining a relative compactness, to significantly improve handling performance.

Advantages: simplicity, low cost, small unsprung masses, a successful scheme for various layout solutions in small spaces.

Disadvantages: noise, low reliability, low roll compensation ("peck" when braking and "squat" when accelerating).

8. Dependent suspension.

The dependent suspension is mainly used for the rear axle. It is used as a front suspension on jeeps. This type of suspension was the main one until about the thirties of the 20th century. They also included coil springs. The problems associated with this type of suspension relate to the large mass of unsprung parts, especially for the axles of the driven wheels, as well as the inability to provide optimal wheel alignment angles.

FROMthe oldest type of suspension. Its history dates back to carts and carts. Its main principle is that the wheels of one axle are interconnected by a rigid beam, most often called a "bridge".

In most cases, if you do not touch on exotic schemes, the bridge can be fixed both on springs (reliable, but not comfortable, rather mediocre handling) and on springs and guide levers (only slightly less reliable, but the comfort and controllability becomes much more) ... It is used where something really strong is required. After all, nothing has been invented yet stronger than a steel pipe, in which, for example, drive axle shafts are hidden. In modern passenger cars, it practically does not occur, although there are exceptions. Ford Mustang, for example. It is used more often in SUVs and pickups (Jeep Wrangler, Land Rover Defender, Mercedes Benz G-Class, Ford Ranger, Mazda BT-50, and so on), but the tendency towards a general transition to independent schemes is visible with the naked eye - handling and speed are now in demand more than the "armor-piercing" of the structure.

Advantages: reliability, reliability, reliability and again reliability, simplicity of design, constant track and ground clearance (off-road this is a plus, not a minus, as for some reason many believe), large moves that allow you to overcome serious obstacles.

Disadvantages: When working out irregularities and in turns, the wheels always move together (they are rigidly connected), which, together with high unsprung masses (a heavy bridge is an axiom), does not have the best effect on the stability of movement and controllability.

On a transverse spring

This very simple and cheap type of suspension was widely used in the first decades of the development of the car, but as speeds increased, it almost completely fell out of use.

The suspension consisted of a continuous beam of the bridge (leading or not leading) and a semi-elliptical transverse spring located above it. In the suspension of the drive axle, it became necessary to place its massive gearbox, so the transverse spring had the shape of a capital letter "L". To reduce spring compliance, longitudinal jet thrust was used.

This type of suspension is best known for Ford T and Ford A / GAZ-A vehicles. This type of suspension was used on Ford vehicles up to and including the 1948 model. The GAZ engineers abandoned it already on the GAZ-M-1 model, created on the basis of the Ford B, but with a completely redesigned suspension on longitudinal springs. The rejection of this type of suspension on a transverse spring in this case was due to the greatest extent to the fact that, according to the experience of operating the GAZ-A, it had insufficient survivability on domestic roads.

On longitudinal springs

This is the most ancient version of the suspension. In it, the bridge beam is suspended on two longitudinally oriented springs. The bridge can be either leading or not leading, and is located both above the spring (usually on cars) and under it (trucks, buses, SUVs). As a rule, the axle is fastened to the spring using metal clamps approximately in its middle (but usually with a slight forward displacement).

The spring in its classic form is a package of elastic metal sheets, connected with clamps. The sheet on which the spring attachment ears are located is called the root - as a rule, it is made the thickest.

In recent decades, there has been a transition to small or even single-sheet springs, sometimes non-metallic composite materials (carbon fiber reinforced plastics and so on) are used for them.

With guide levers

There are a variety of schemes of such suspensions with different number and arrangement of levers. The five-link dependent suspension with Panhard rod shown in the figure is often used. Its advantage is that the levers rigidly and predictably set the drive axle movement in all directions - vertical, longitudinal and lateral.

More primitive options have less leverage. If there are only two levers, during the operation of the suspension they tilt, which either requires their own flexibility (for example, on some Fiats of the early sixties and English sports cars, the levers in the spring rear suspension were made elastic, plate, in fact, similar to quarter-elliptical springs) , or a special articulated connection of the levers with the beam, or the flexibility of the beam itself to torsion (the so-called torsion-bar suspension with coupled levers, which is still widespread on front-wheel drive cars

As elastic elements, both coil springs and, for example, air bellows can be used (especially on trucks and buses, as well as - flowriders)... In the latter case, a rigid setting of the movement of the suspension guide vane in all directions is required, since the air bellows are not able to perceive even small lateral and longitudinal loads.

9. De-Dion type dependent suspension.

Firm "De Dion-Bouton" in 1896 developed a rear axle design, which made it possible to separate the differential housing and the axle. In the suspension of the "De Dion-Bouton" design, the torque was perceived by the bottom of the car body, and the drive wheels were attached to the rigid axle. With this design, the mass of non-shock-absorbing parts was significantly reduced. This type of suspension was widely used by Alfa Romeo. It goes without saying that such a suspension can only work on the rear drive axle.

Suspension "De Dion" in a schematic image: blue - continuous suspension beam, yellow - final drive with differential, red - axle shafts, green - hinges on them, orange - frame or body.

Suspension "De Dion" can be described as an intermediate type between dependent and independent suspensions. This type of suspension can be used only on drive axles, more precisely, only the drive axle can be of the De Dion type, since it was developed as an alternative to the continuous drive axle and implies the presence of driving wheels on the axle.

In the "De Dion" suspension, the wheels are connected by a relatively light, somehow sprung continuous beam, and the final drive gearbox is fixedly attached to the frame or body and transmits rotation to the wheels through axle shafts with two hinges on each.

This allows unsprung masses to be kept to a minimum (even when compared to many independent suspensions). Sometimes, to improve this effect, even the brakes are transferred to the differential, leaving only the wheel hubs and the wheels themselves unsprung.

During the operation of such a suspension, the length of the axle shafts changes, which forces them to be performed with hinges of equal angular velocities movable in the longitudinal direction (as on front-wheel drive cars). The English Rover 3500 used conventional universal joints, and to compensate, the suspension beam had to be made with a unique sliding joint design, which allowed it to increase or decrease its width by several centimeters when the suspension was compressed and rebounded.

"De Dion" is a technically very advanced type of suspension, and in terms of kinematic parameters it surpasses even many types of independent ones, yielding to the best ones only on uneven roads, and then in some indicators. At the same time, its cost is quite high (higher than that of many types of independent suspension), so it is used relatively rarely, usually on sports cars. For example, many Alfa Romeo models had such a suspension. A recent car with such a suspension is Smart.

10. Dependent suspension with drawbar.

This suspension can be considered as semi-independent. In its current form, it was developed in the seventies for compact cars. For the first time this type of axle was serially installed on the Audi 50. Today, an example of such a car is the Lancia Y10. The suspension is assembled on a tube bent in front, at both ends of which wheels with bearings are mounted. The forward bend forms the actual drawbar, which is fixed to the body with a rubber-metal bearing. Lateral forces are transmitted by two symmetrical oblique jet rods.

11. Dependent suspension with tied arms.

The linked-arm suspension is an axle that is a semi-independent suspension. The suspension has rigid trailing arms connected to each other by a rigid elastic torsion bar. This design, in principle, makes the levers vibrate in sync with each other, but by twisting the torsion bar it gives them some degree of independence. This type can be conventionally considered semi-dependent. In this form, the suspension is used on the Volkswagen Golf. In general, it has many types of design and is very widely used for the rear axle of front-wheel drive vehicles.

12. Torsion bar suspension

Torsion bar suspension - these are metal torsion shafts operating in torsion, one end of which is attached to the chassis, and the other is attached to a special perpendicularly standing lever connected to the axle. The torsion bar suspension is made of heat treated steel, which can withstand significant torsional loads. The basic principle of the torsion bar suspension is bending.

The torsion beam can be positioned longitudinally and transversely. The longitudinal torsion bar suspension is mainly used on large and heavy trucks. On passenger cars, as a rule, a transverse arrangement of torsion suspensions is used, usually on a rear wheel drive. In both cases, the torsion bar suspension provides a smooth ride, regulates roll when cornering, provides an optimal amount of damping of oscillations of the wheels and body, and reduces oscillations of the steered wheels.

On some vehicles, the torsion bar suspension is used for automatic alignment using a motor that pulls the beams together to add stiffness based on speed and road conditions. The height-adjustable suspension can be used when changing wheels where the vehicle is raised with three wheels and the fourth is raised without a jack.

The main advantages of torsion suspensions are durability, ease of height adjustment and compactness across the width of the vehicle. It takes up significantly less space than coil springs. The torsion bar suspension is very easy to operate and maintain. If the torsion bar suspension is loose, then you can adjust the positions using a conventional wrench. It is enough to climb under the bottom of the car and tighten the necessary bolts. However, the main thing is not to overdo it in order to avoid excessive rigidity when driving. Adjusting torsion bar suspensions is much easier than adjusting spring suspensions. Car manufacturers are changing the torsion beam to adjust travel position based on engine weight.

The prototype of the modern torsion bar suspension can be called the device that was used in the Volkswagen Beatle in the 30s of the last century. This device was modernized by the Czechoslovak professor Ledvinka to the design we know today and was installed on the Tatra Mountains in the mid-1930s. And in 1938, Ferdinand Porsche copied the design of Ledwinky's torsion bar suspension and introduced it into the mass production of the KDF-Wagen.

The torsion bar suspension was widely used on military equipment during the Second World War. After the war, automotive torsion bar suspension was used mainly on European cars (including passenger cars) such as Citroen, Renault and Volkswagen. Over time, passenger car manufacturers abandoned the use of torsion suspensions on passenger cars due to the complexity of manufacturing torsion bars. These days, torsion bar suspension is mainly used on trucks and SUVs from manufacturers such as Ford, Dodge, General Motors and Mitsubishi Pajero.

Now about the most common misconceptions.

"The spring sagged and became softer":

- No, the spring rate does not change. Only its height changes. The turns get closer to each other and the machine sinks lower.

- "The springs are straightened, so they sagged": No, if the springs are straight, this does not mean that they are sagging. For example, on the factory assembly drawing of the UAZ 3160 chassis, the springs are absolutely straight. At Hunter, they have a bend of 8mm, which is barely noticeable to the naked eye, which, of course, is also perceived as "straight springs". In order to determine whether the springs have sagged or not, you can measure some characteristic size. For example, between the bottom surface of the frame above the bridge and the surface of the bridge stocking under the frame. Should be about 140mm. And further. These springs are not conceived by direct chance. When the axle is located under the spring, only in this way can they provide a favorable floatability characteristic: when heeling, do not steer the axle towards oversteer. You can read about understeer in the "Vehicle handling" section. If in some way (by adding sheets, forging resors, adding springs, etc.) to achieve that they become curved, then the car will be prone to yaw at high speed and other unpleasant properties.

- "I will cut off a couple of turns from the spring, it will sag and become softer": Yes, the spring will indeed become shorter and it is possible that when installed on a car, the car will sag lower than with a full spring. However, in this case, the spring will not become softer but, on the contrary, harder in proportion to the length of the sawn bar.

- “I will add springs (combined suspension) to the springs, the springs will relax and the suspension will become softer. During normal driving, the springs will not work, only the springs will work, and the springs will only work at maximum breakdowns " : No, the stiffness in this case will increase and will be equal to the sum of the stiffness of the spring and the spring, which will negatively affect not only the comfort level but also the cross-country ability (about the effect of suspension stiffness on comfort later). In order to achieve a variable suspension characteristic with this method, it is necessary to bend the spring to the free state of the spring and bend through this state (then the spring will change the direction of force and the spring and spring will begin to work at the spring). And for example, for a UAZ small leaf spring with a stiffness of 4 kg / mm and a sprung mass of 400 kg per wheel, this means a suspension lift of more than 10 cm !!! Even if this terrible lift is carried out with a spring, then in addition to the loss of stability of the car, the kinematics of the curved spring will make the car completely uncontrollable (see paragraph 2)

- "And I (for example, in addition to item 4) will reduce the number of sheets in the spring": The reduction in the number of sheets in the spring really clearly means a decrease in the stiffness of the spring. However, firstly, this does not necessarily mean a change in its bending in a free state, secondly, it becomes more prone to S-shaped bending (winding water around the bridge by the action of the reactive moment on the bridge) and thirdly, the spring is designed as a "beam of equal resistance bending "(who studied" SoproMat ", he knows what it is). For example, 5-leaf springs from the Volga-sedan and more rigid 6-leaf springs from the Volga-station wagon have the same root leaf only. It would seem that in production it is cheaper to unify all parts and make only one additional sheet. But this is not possible because if the condition of equal resistance to bending is violated, the load on the spring sheets becomes uneven in length and the sheet quickly fails in a more loaded area. (The service life is shortened). I do not recommend changing the number of sheets in a package, and even more so to collect springs from sheets from different brands of cars.

- "I need to increase the rigidity so that the suspension does not break through to the bumpers" or "the SUV must have a rigid suspension." Well, first of all, they are called "chippers" only in the common people. In fact, these are additional elastic elements, i.e. they stand there specifically so that they can be pierced and so that at the end of the compression stroke the stiffness of the suspension increases and the necessary energy consumption is provided with a lower stiffness of the main elastic element (springs / springs). With an increase in the rigidity of the main elastic elements, the permeability also deteriorates. It would seem what is the connection? The traction limit for adhesion that can be developed on a wheel (in addition to the coefficient of friction) depends on the force with which this wheel is pressed against the surface on which it is traveling. If the car is driving on a flat surface, then this pressing force depends only on the mass of the car. However, if the surface is not level, this force begins to depend on the stiffness characteristic of the suspension. For example, imagine 2 cars of equal sprung mass, 400 kg per wheel, but with different stiffness of the suspension springs 4 and 2 kg / mm, respectively, moving on the same uneven surface. Accordingly, when driving through an unevenness with a height of 20 cm, one wheel worked for compression by 10 cm, the other for rebound by the same 10 cm. When the spring with a stiffness of 4kg / mm is expanded by 100mm, the spring force decreased by 4 * 100 \u003d 400kg. And we have only 400kg. This means that there is no traction on this wheel, but if we have an open differential or a limited-friction differential (DOT) on the axle (for example, a screw "Quife"). If the stiffness is 2 kg / mm, then the spring force has decreased only by 2 * 100 \u003d 200 kg, which means that 400-200-200 kg is still pressing and we can provide at least half the thrust on the axle. Moreover, if there is a bunker, and most of them have a blocking coefficient of 3, if there is some kind of traction on one wheel with the worst traction, 3 times more torque is transmitted to the second wheel. And an example: The softest UAZ suspension on small-leaf springs (Hunter, Patriot) has a stiffness of 4kg / mm (both spring and spring), while the old Range Rover has about the same mass as the Patriot, on the front axle 2.3 kg / mm, and on the back 2.7kg / mm.

- "Passenger cars with soft independent suspension should have softer springs." : Not at all necessary. For example, in a MacPherson-type suspension, the springs really work directly, but in suspensions with double wishbones (front VAZ-classic, Niva, Volga) through a gear ratio equal to the ratio of the distance from the lever axis to the spring and from the lever axis to the ball joint. With this arrangement, the stiffness of the suspension is not equal to the stiffness of the spring. The spring rate is much higher.

- “It is better to use stiffer springs so that the car is less rolly and therefore more stable” : Not certainly in that way. Yes, indeed, the greater the vertical stiffness, the greater the angular stiffness (which is responsible for body roll under the action of centrifugal forces in turns). But the transfer of masses due to body roll affects the stability of the car in a much lesser way than, say, the height of the center of gravity, which Jeepers often throw very wastefully to lift the body just in order not to cut the arches. The car must roll, roll is not bad. This is important for informative driving. Most cars are designed with a standard roll of 5 degrees at a peripheral acceleration of 0.4g (depending on the ratio of the turning radius to the speed). Some automakers use a smaller roll angle to create the illusion of stability for the driver.

Car suspension - one of the most important components of the car, about the properties and importance of which it makes no sense to speak again. Since it is the suspension that is the most important link that connects the car body (frame) to the road surface.

The most basic function of the suspension is:

1. Coupling the wheel to the frame or body.

2. The suspension provides the necessary smoothness of movement and the necessary travel (movement) of the wheels in relation to the load-bearing part of the vehicle.

3. Transfer of moments and force, which occurs when the wheels and the road interact, to the bearing part of the machine.

The main properties of the suspension:

2. Elasticity - the perception and direction of vertical reaction forces that arise when the road is uneven.

3. Depreciation - it is necessary to damp the vibrations of the load-bearing part of the car, which arise due to poor road conditions.

Automotive suspension classification

There are two main types of car suspension: dependent and independent suspension. In turn, each type of suspension, depending on the purpose and functionality, is divided into various modifications and types.

The dependent car suspension is a special design, the principle of operation, which consists in rigidly interconnected both axle wheels. Moving each of them, one way or another, will affect the other.

What is independent suspension? This design option implies the autonomy (independence) of each of the wheels from each other. Being on the same axle, the wheels are not connected in any way, and practically do not affect the position and operation of each of them. Setting parameters: wheel camber, track, base during independent suspension operation may change.

The modern suspension of the car has seriously evolved, and today it is a rather complex and almost perfect structure, capable of simultaneously combining hydraulic, mechanical, pneumatic and electrical qualities. With the advent of electronic systems, suspension control became available to the driver, with the help of which it is possible to achieve the most accurate suspension adjustment, for a comfortable or, on the contrary, more aggressive driving and handling.

Consider the main types of car suspensions

Dependent car suspension. As an example of this type of suspension, we can consider, for example, the rear dependent suspension, which are equipped with rear-wheel drive cars, for example, Zhiguli "classic". The main disadvantage of this option is the large weight of the structure, moreover, if the bridge performs the function of the driving axle, smoothness will be lost.

Among such devices, there are also conditionally intermediate suspension variations. Representatives of this class are semi-independent and semi-independent suspension.

Semi-independent suspension or torsion bar, often used in the production of compact cars. This suspension option is a cross between a trailing arm suspension and a dependent suspension. Moreover, besides being concerned with the perception of lateral forces, it also acts as a stabilizer.

Semi-independent rear vehicle suspension. Why exactly the back one? Because this type of suspension is used exclusively at the rear. The design itself is: two trailing arms, which are interconnected in the middle by means of a cross member. This type of suspension is only used on non-drive axles. Among the advantages of this type of suspension: compactness, lightness and ease of installation.

Independent car suspension. The traditional and at the same time the most common type of independent suspension, which is used in mass production, and is installed on most modern front-wheel drive cars, is McPherson (MacPherson), this is a double-wishbone, as well as a multi-link suspension version.

Each of the above types of suspension has its own advantages, disadvantages and features. The most effective, perhaps, is the multi-link type of car suspension, but it has a high cost and is expensive to manufacture, usually used on executive or premium cars.

Summing up

Summarizing the above, we can conclude that, by and large, for the broad masses, as a rule, it is not so important how many levers the front or rear suspension of his car is equipped with, the most important thing is that the car performs its main function and is at the same time: comfortable, safe , a convenient and reliable means of transportation.

5 (100%) 2 vote [s]